|

Tel: +86 20 36013580

+86 20 36013581

+86 20 36013445

Fax: +86 20 36013583

Email: sales@dkirubber.com |

|

| Home > O ¨C Rings & Basic Seals > O-Ring |

|

| |

O-Ring |

| |

Simple and Versatile Seal |

| |

DKI precision O-Rings are used extensively throughout industry where pressures, temperatures and tolerances are critical.

Our O-Rings are specially manufactured for both static and dynamic applications and offer a wide range of properties, including excellent compression set characteristics, ability to withstand aggressive process media, and a long trouble-free operating life.

DKI's high performance o-rings are available in a variety of advanced materials: NBR(Buna-N), HNBR, FKM, Silicone, EPDM, PTFE(PTFE), Encapsulated O-Ring,etc, in both standard and custom sizes. |

|

| |

|

| |

|

| |

|

| |

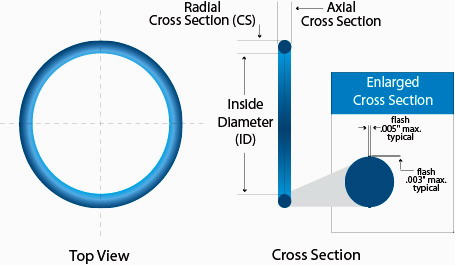

O-Ring Application Functional Description

An o-ring is a simple and versatile ring-shaped packing or sealing device with a circular cross section, from which the "O" in its name is derived. O-rings function as compact and reliable sealing devices by absorbing the tolerance stack-up between closely mated surfaces in both dynamic (moving) and static (stationary) applications.

An o-ring seals by blocking any potential leak path of a fluid (liquid or gas) between two closely spaced surfaces. The o-ring is generally installed in a machined groove in one of the surfaces to be sealed. As the two surfaces are brought together, forming a gland, they squeeze the cross section of the o-ring. |

| |

| |

|

| |

Static Sealing |

Most O-Rings are used in static service (the O-Ring and metal surfaces remain relatively fixed). They may be applied as face seals or radial seals. In face seal applications, the O-Ring should seat against the low pressure side of the groove. |

| |

|

| |

Dynamic Sealing |

The O-Ring moves relative to the mating surface. A moving seal may be further classified by the type of motion: reciprocating, oscillating, or rotating. The greatest number of dynamic seals are used in reciprocating service in cylinders, valves, and linear actuators. Oscillating motion is encountered in swivels and valve stems. When an O-Ring is used on a rotating shaft, it should be limited to light duty where the shaft speed is low and some fluid bypass is acceptable. |

| |

|

| |

Durometer Selection |

70-durometer hardness should be used wherever possible as it offers the best combination of properties for most O-Ring applications. Softer compounds stretch easier and seal better on rough surfaces. Harder compounds offer greater abrasion resistance and resistance to extrusion.

If you require further information or enquire, please contact us. Simply call us on: +8620 36013580, or e-mail us: sales@dkirubber.com. |

| |

|

| |

|

| |

|

| |

|

|